Wow. What a year.

First off, I gotta apologize to folks trying to follow my progress who're not on Instagram! I've been kinda AWOL on my own blog...but you know how it goes with constantly-evolving social media. IG has been a great space to share not only my day-to-day exploits in the world of custom toy-making, but also a little more about myself through pictures of the many amazing Japanese robot and monster toys I've accumulated over the years. And even a little hip hop music here and there. ;) It's so damn simple to post something fresh every day or two. Makes this blog seem clunky in comparison!

But on the strength, this blog is still my secret base of operations for whenever I need to dump a massive wall of text (like this one!) or mad pics that wouldn't be appropriate elsewhere. I can announce stuff on IG, but I'll always refer back to this blog for more info, contacting me, or buying something.

I just want it to be clear that even though my blog posts are sporadic as hell, that's definitely NOT an indication that my toy-making adventures are slowing down in any way! Word. Life. In fact, it's now been about eight months since I followed Ben's lead and bought an Afinia H-series 3D printer. And to call it a "game-changer" would be an understatement bordering on absurdity.

See, lemme explain something. I don't give a crap about 3D printing. I don't give a crap about CAD modeling. What I care about is making toys, y'knowmsayin? That's it. As it turns out, I happen to be kinda nice with CAD...given that I've been working deep in the CAD software industry for over a decade. And I've been collecting and dreaming about Japanese toys for FAR longer. But while collecting these things has hooked me up with a great group of people, once my creative side started to assert itself over my consumeristic nature, I knew I had to make at least some of the craziness dancing in my head real.

But I just never got into resin- or rubber-casting. You can make some dope little rubber guys...but the process is very slow and labor-intensive. $15-20 for a 2" non-articulated minifig that you have to wait in line for is a far cry from buckets of MUSCLE dudes available on eBay for a buck or two. No hate, of course--I love what cats like MUSCLEThings.com, Eric Nilla, and Tru:Tek/Zectron are doing. But that's not my path.

I don't wanna do vinyl either. There are some amazingly-beautiful Japanese slush-cast vinyl figures being produced by today's hottest artists, for sure. These are made using the same gloriously out-dated, inefficient techniques used in making the original Bullmark (and others) kaiju toys of the 60's and 70's. It's amazing to me that they're keeping this tradition of slush-casting alive--it's a small historical and pop-cultural treasure of Japan's, if you ask me. But this isn't the route I wanna take either. Spending $5k on a mold for a single figure isn't what I really want--especially when that means I'll have to request tiny batches of these figures to be cast in a million different colors, have them painted by...someone...and then sell them over and over to the same group of 50 people for $100+ a whack. That's fine for many others...but not me.

And mass production? Well, there's rotocast vinyl or injection-molded PVC in China...both viable options, as seen by what Onell Design has accomplished over the last six years. But again, extremely high start-up costs lock an artist into just a handful of designs that they're forced to push hard just to recover the initial investment. I want to be more dynamic. Keep releasing new material...never bogged down in marketing or politics.

Which brings me to 3D printing. It's kind of amazing to have had this brand new medium just fall into my lap. And THAT is what it really is to me: a medium for making custom toys. This is where I differ from so many folks I've met over the past six months in the 3D printing game: I don't care about 3D printing, in and of itself. Whether you wanna call me an "artist" or a "toy-maker"...it doesn't really matter to me. The point is that my passion is the toys--not the method used to make them. I get that 3D printing is this new, emerging technology, and that playing with a consumer-grade home printer is a fun hobby...but that ain't what this is.

...

2014 will be a big year for me. I can already tell. Seeds planted almost a year ago now are getting VERY close to sprouting! But before I get into that, I have some kinda somber news to announce: I'm officially pulling the plug on Foe-Gokin Gin Gin. I started this blog about three and a half years ago as a way to track the development of a locally-manufactured, Popy chogokin-style toy of Saucer Animal Gin Gin, my favorite villain from the 70's super robot anime, UFO Robo Grendizer. Those 3+ years saw a LOT of overhauled strategies, a lot of setbacks, a lot triumphs, and most importantly, a lot of learning. All in all, it was a great project to cut my teeth on, and even though I only made a couple official releases, I feel satisfied with everything this effort has taught me.

So why pull the plug? Well, it mostly comes down to economics. I won't go into the details of the manufacturing process, but suffice it to say that the resources necessary for a fully-painted release would have *forced* the price up to somewhere around $200. And while the end result would have been nice, it wouldn't have good enough for me. The heft of all that pewter content was fantastic, but without more articulation and gimmickery, it would have felt more like a painted statue or bust than a fully-realized chogokin toy. So the bottom line is pretty simple: if I were a consumer, I would NOT have bought one for that kinda money.

Oh, there's one more reason to abandon this project: HL Pro/High Dream has now made a fully-licensed Gin Gin toy of their own! Sure, it's not quite the format/style I would have wanted in a Gin Gin figure, but the whole idea of my "Foe Gokin" line was to create toys of our favorite hero robots' enemies--characters who previously were never made into toys. But now that there's a high-quality Gin Gin toy on the market, well, that itch has now been scratched!

But all that having been said, stick around. You may just see another shield-wielding super robot emerge from Gin Gin's ashes... ;)

Aiiyo, but before I finally send Foe Gokin Gin Gin beyond the veil, I just want to say one more thing. Homemade chogokin CAN be done. If the last three years have taught me anything, it's that this sort of custom toy *can* be realistically made. I've proven it. I already talked about why pursuing this project doesn't make sense for me...but I want to make it clear that if ANYONE out there wants to pursue making a custom chogokin toy, please don't hesitate to drop me a line. In all that time, I've learned a TON about this process, and I would personally *love* to see someone design and produce the equivalent of a homegrown "diecast" toy (well, a pewter toy cast in a vulcanized rubber mold). It would greatly honor the efforts of the past three years for me to help in any way I can.

...

Okay, now for the good stuff!

Looking ahead at 2014, there's going to be a LOT more direct 3D-printed toys coming from myself, Ben "Prometheum5" Mininberg, and David "Mechazone" White. We're forming a bit of a Getter team when it comes to spearheading this medium. And obviously, I'm Ryoma. David and Ben can brawl to figure out who's Benkei. ;)

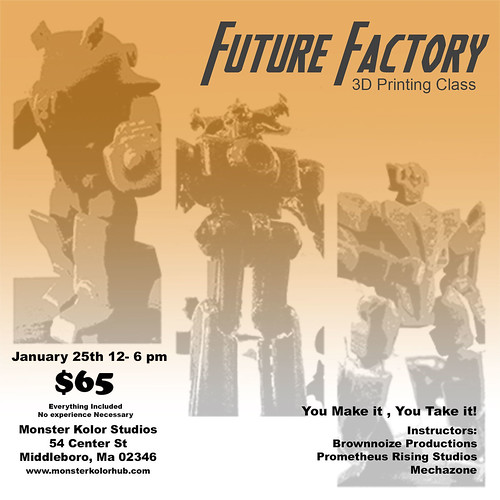

But yo, check this out: this announcement may be a bit late, but I'm actually teaching a 3D printing class next month at Monster Kolor Studios.

Ben and David will be assisting in this epic, first-of-its-kind event. We'll be talking a little about ourselves and how we got into this mess...but the meat of the class will be a *complete* breakdown of all the steps necessary for manufacturing a robot toy using a home/consumer-grade FDM (fused deposition modeling) printer. We'll cover the actual printing process, cleaning up the parts directly from the machine, and treating them with acetone vapor. And like the flyer above says, you make it, you take it! Yes, every student gets to select a robot toy design from one of us, and over the course of the class, prints it, cleans it up, and AVBs it (acetone vapor bathes it). And you take home the toy you just made. That's kinda hot!

Like I said, the announcement's a bit late because, well, the class sold out about six hours after announcing it! So *clearly*, there's some interest in this stuff! For now, we're telling folks to come on down even if they missed out--even if you're not a paying student with space on a printer, you get to watch the whole process and participate like anyone else. And we're most definitely planning on doing MOAR Future Factory classes and other events like it as time goes by. Our goal is twofold. We want to demystify CAD modeling and 3D printing, and ultimately, to get more folks involved in this medium for custom toy-making. But we're also trying to bridge the gap between the designer/custom toy people (usually resin/rubber or vinyl collectors who prefer the artistry and communal aspects of these toys) and the mass-marketed robot toy-collecting people (usually TF or vintage chogokin collectors who enjoy the accessibility and depth of the fandom).

2014 will also be the year of the Powered Bio Suit! Development of this toy has been frighteningly fast and relatively painless. Not to mention surprisingly inexpensive! The stickers are done. The packaging is about 99% done. The toys, themselves are pretty much ready to go. The production versions of these suits might just make their debut at the Future Factory class... Stay tuned!

And lastly, here's a bit of a teaser for a new toy line I'll be producing next year (again, debuting at Future Factory):

In fact, students of the class will be able to pick from among these characters to print--or mix and match body parts!

That's it for now. Have a great New Year's celebration, enjoy the weather, and keep it gully. See you in '14!